Industrial Vacuum Tumbler: Complete Specifications and Technical Guide

Product Overview

Industrial vacuum tumblers are essential equipment for modern meat processing, designed to enhance flavor infusion and improve product quality through advanced vacuum tumbling technology.

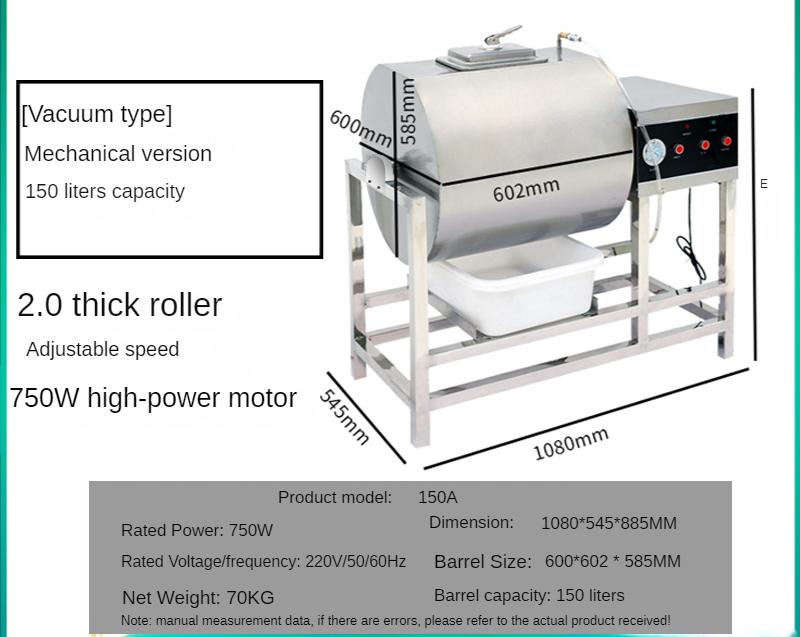

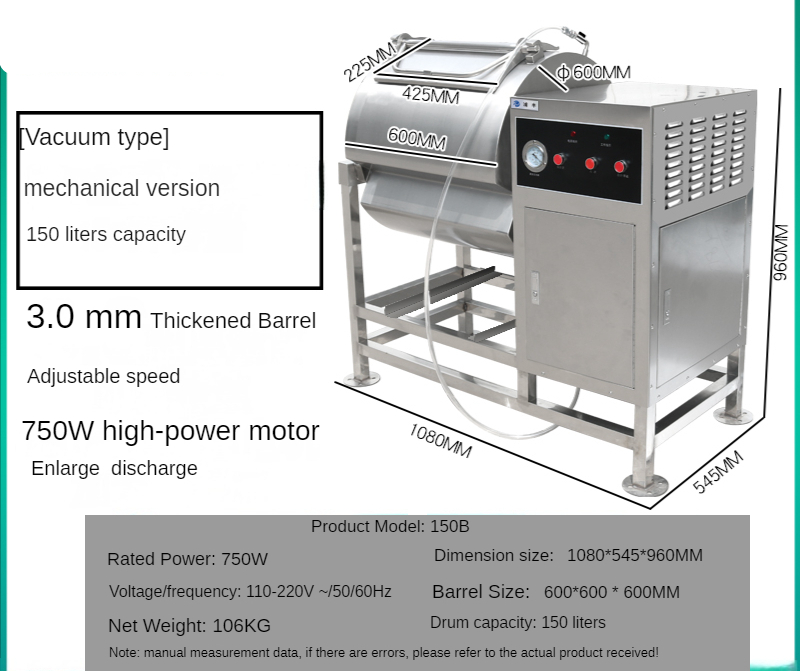

Technical Specifications

| Computer Version | Dimension (mm) | Barrel Size (mm) | Power (w) |

|---|---|---|---|

| 18L | 650×300×450 | 325×300×250 | 25w |

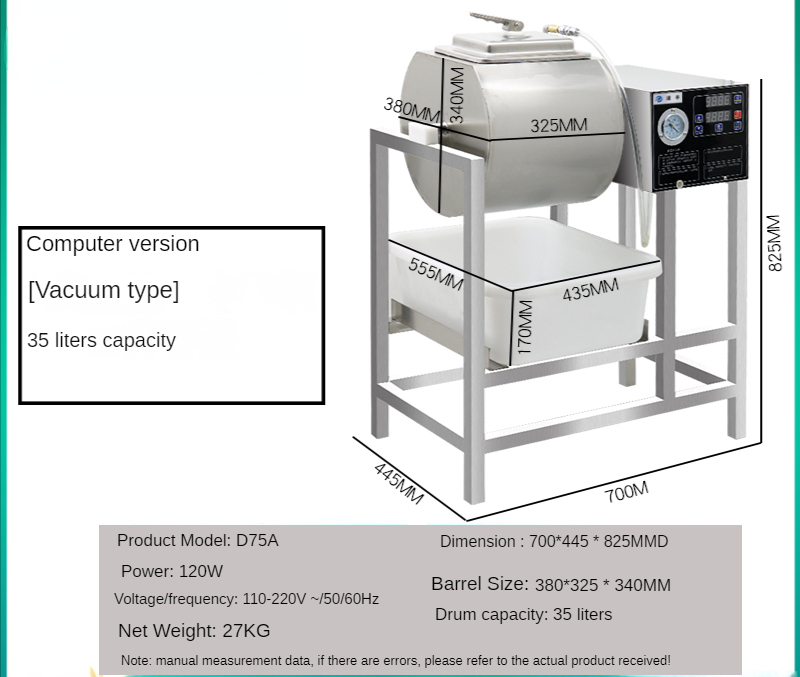

| 35L | 700×445×890 | 325×380×345 | 120w |

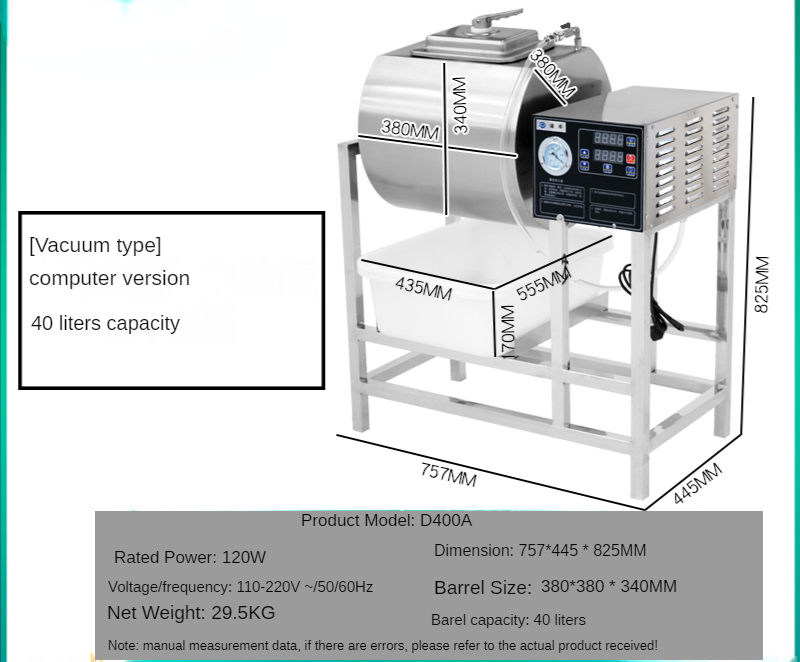

| 40L | 870×450×890 | 380×380×340 | 120w |

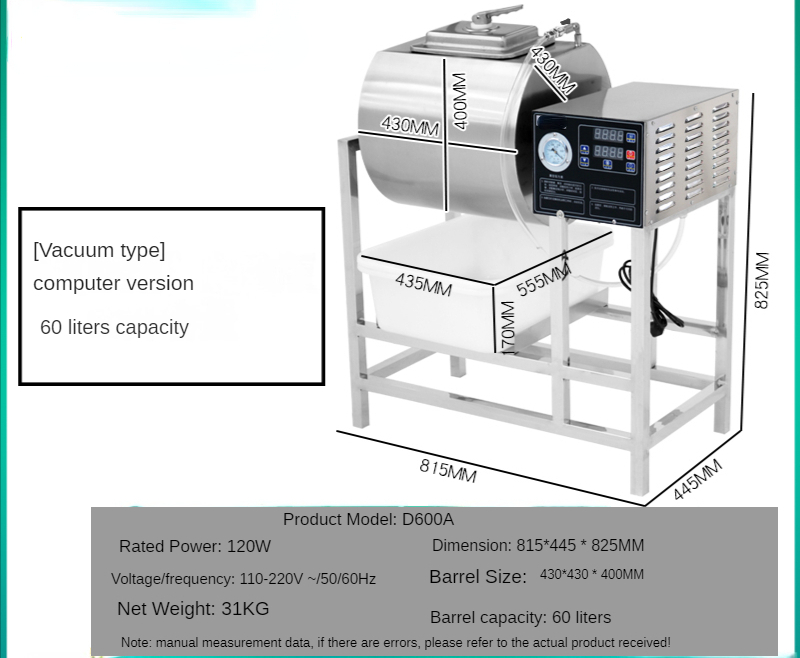

| 60L | 921×455×920 | 430×430×400 | 120w |

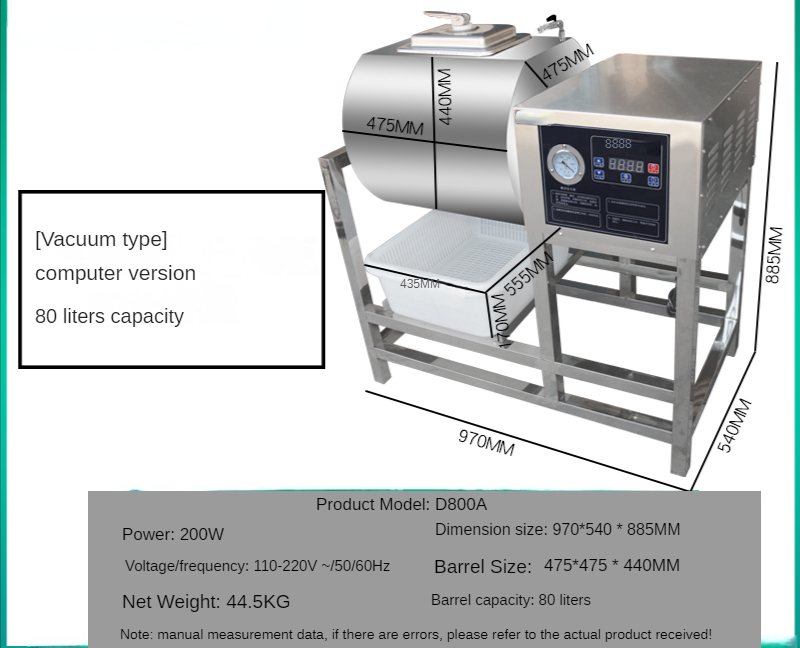

| 80L | 970×550×955 | 475×475×450 | 200w |

| 100L | 1065×545×885 | 500×530×475 | 750W |

| 150L | 1080×454×1025 | 602×600×585 | 750W |

Optimize Your Production with an Industrial Vacuum Tumbler

An industrial vacuum tumbler is a cornerstone of efficiency and quality in modern food processing. If you are searching for a commercial vacuum tumbler or comparing the vacuum tumbler machine price, understanding its core benefits is the first step toward making a strategic investment. This machine is engineered to significantly enhance the flavor, texture, and yield of meat products, making it indispensable for producers of bacon, ham, poultry, and marinated meats.

How Does a Vacuum Meat Tumbler Work?

The principle is both simple and highly effective. The vacuum tumbler machine places meat and marinade in a sealed drum. By creating a powerful vacuum, the machine removes air from within the meat's cellular structure. As the drum rotates, the meat is gently tumbled, allowing the brine or seasoning to be forced deep into the fibers under the pressure differential. This process, known as vacuum tumbling, achieves in minutes what used to take hours with traditional static marination. The result is a perfectly seasoned product with dramatically improved tenderness, juiciness, and a more consistent color throughout.

Key Advantages of a Commercial Vacuum Tumbler

The primary reason businesses invest in a commercial vacuum meat tumbler is the substantial increase in product yield. The vacuum pressure ensures maximum absorption of the marinade, directly impacting your bottom line. Furthermore, the mechanical action of the meat tumbler machine naturally breaks down muscle fibers, resulting in a remarkably tender product without the need for additives. For operations of all sizes, from a bustling hotel kitchen to a large-scale processing plant, this technology ensures batch-to-batch consistency, reduces labor costs, and accelerates production timelines.

Choosing the Right Machine for Your Needs

When selecting equipment, it's crucial to consider capacity and features. Whether you need a compact model for a specialized operation or a large industrial vacuum tumbler for high-volume output, there are models designed to fit. While some may look for a used vacuum tumbler to manage initial costs, investing in a new machine from a reputable supplier ensures reliability, modern efficiency, and manufacturer support. The price of a vacuum tumbler machine is an investment that pays for itself through reduced waste, superior product quality, and increased throughput.

Upgrade Your Food Processing Today

Upgrade your food processing capabilities today. An industrial vacuum tumbler is not just a machine; it's a commitment to producing higher-quality, more profitable, and delicious meat products.